ASSISTING BUSINESSES IN FINDING STORAGE OPTIONS

Protection Strategy to Lithium-ion Battery Storage in Warehouse Rack

During plan review of pallet rack and other types of storage rack permit submittals, additional information is frequently requested by the jurisdictions reviewing Building or Fire Department with regard to the hazards of lithium-ion (li-ion) batteries, intended operations at the facility, warehouse storage arrangements, and fire protection strategy.

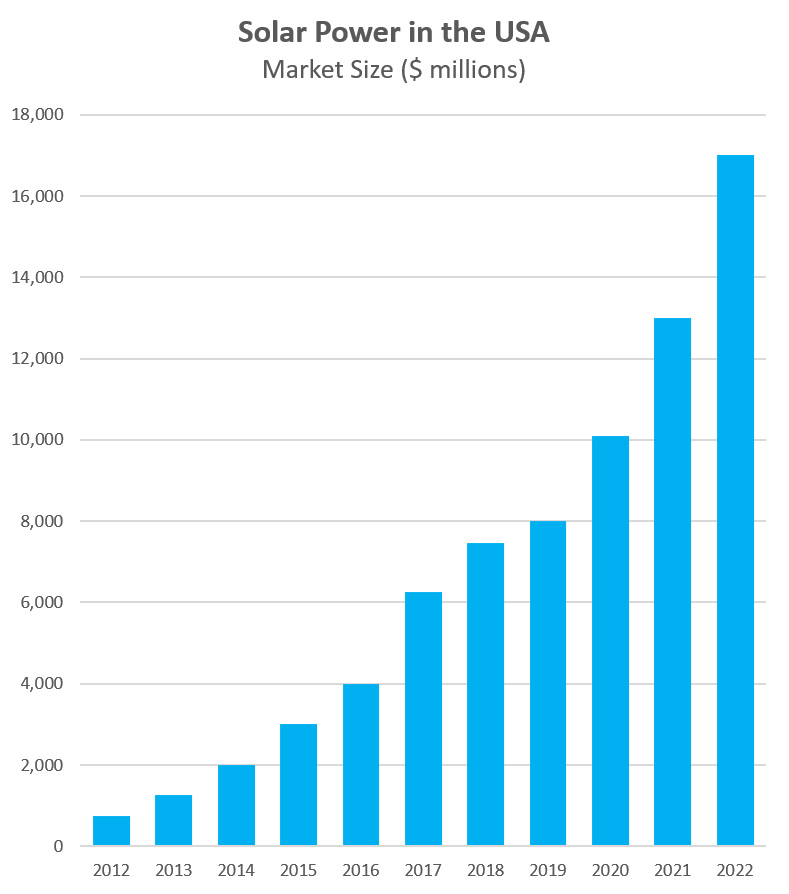

Many solar provider companies have requested through their warehousing / material handling rack suppliers that a qualified fire protection firm prepare a general review of the fire code requirements related to their potential storage of li-ion batteries commonly used throughout the solar industry.

The Fire Protection International Consortium, Inc. (FPI), a fire protection consulting engineering firm, has extensive experience with lithium-ion batteries in warehouse storage, in use, and in the manufacturing process. FPI has completed similar fire hazards analyses for several manufacturers of lithium-ion batteries, evaluations of protection systems for battery energy storage systems, and developed fire protection design basis for warehousing of new and used lithium-ion batteries.

A typical solar installation and provider company facility design would typically be classified as a Group S-1 storage. The company operations will involve receiving and storing new batteries along with other products associated with their PV solar power installations such as panels, modules, solar racking kits, inverters, optimizers, rail, conduit, wire, electrical components, roofing supplies and construction materials.

Lithium-ion Battery Hazard Analysis

The research on hazards of lithium-ion cells is an on-going effort to understand the dynamics of cell failure, to predict thermal runaway, and to codify appropriate protection of varying configurations. Much of the research focus to date has been directed at testing and developing safe energy storage systems (ESS) used in the electrical power industry. These systems typically have arrays of lithium-ion cells within battery cabinets installed inside of shipping container shaped enclosures. Small scale testing of lithium-ion cells at the cell level and in modules (groups of cells) inside of a battery cabinet has provided the industry with some baseline understanding about fire size, potential propagation, suppression and firefighting techniques, effects of cell chemistry, effects of state of charge, thermal runaway, and vent gas production.

The test program performed by FM Global and NFPA Research Foundation tested lithium-ion batteries in storage. These tests most closely resemble the planned storage at a typical solar installation and provider company warehouse; however, the scope of the tests was limited in height, commodity packaging variability, rack and storage configurations, and other variables affecting fire growth and size. In the absence of all-encompassing tests, the available fire test reports, fire event reports, and research studies were reviewed to assess the fire and explosion risks applicable to the solar provider company warehouse. The following discussion summarizes key findings from this review and provides recommendations for protection.

Before discussing the details, it is important to understand some terminology used when discussing lithium-ion batteries and understand the conclusions of recent research efforts.

Terminology

Cell – A cell is the smallest unit of energy storage within a battery system.

Module – The term module is used when referring to cells that are electrically interconnected.

Battery – A battery is a group of interconnected modules.

State of Charge – State of Charge (SOC) refers to the ratio of the available capacity to the maximum possible charge. A fully charged cell is at 100% SOC and a fully discharged cell is 0% SOC.

Thermal Runaway – Damage to a lithium-ion cell either thermally, mechanically, or electrically can cause an exothermic decomposition of the cell materials. When the self-heating rate of the cell is greater than the rate at which heat can be dissipated, the cell temperature rises exponentially, and stability is lost. The loss in stability results in all remaining thermal and electrochemical energy being released to the surroundings.

Energy Storage System (ESS) – Batteries assembled together, capable of storing energy in order to supply electrical energy at a future time to the local power loads or for grid support.

Lithium-ion Battery Fire and Explosion Hazards

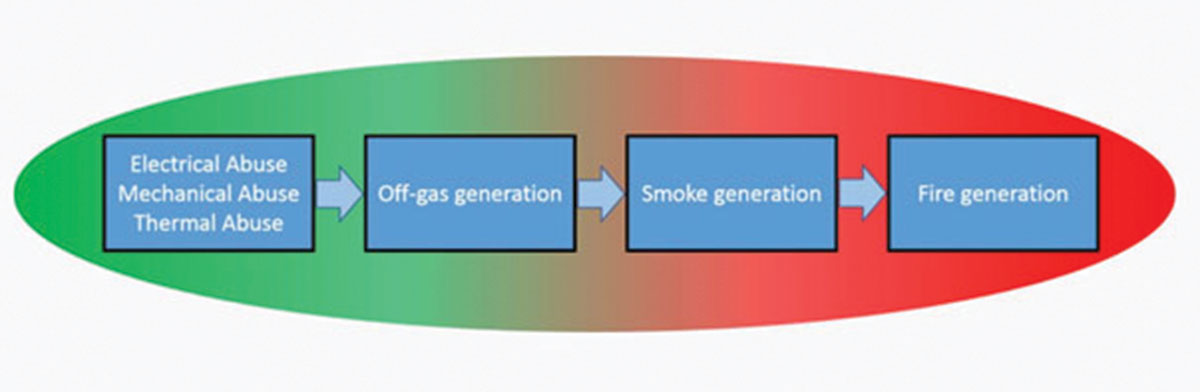

The hazards associated with lithium-ion batteries are now more commonly known thanks to the research efforts of the NFPA Research Foundation, FM Global, and several other organizations. What has been shown through laboratory testing and in post-event analyses is that fires involving lithium-ion cells with a moderate to high charge follow a specific timeline of events. This timeline begins with the original failure mode of either electrical, mechanical, or thermal abuse. Cells then begin a process of off-gas generation as a chemical reaction causes decomposition of the cell materials and the flammable electrolyte is turned to vapor. As the cells continue to self-heat due to the reaction, smoke is generated and finally fire is generated as the cells release the stored energy and the flammable electrolyte becomes involved in the combustion. Thermal runaway is the term used for this process of uncontrolled self-heating.

* Picture of Cell Failure Explosion Scenarios

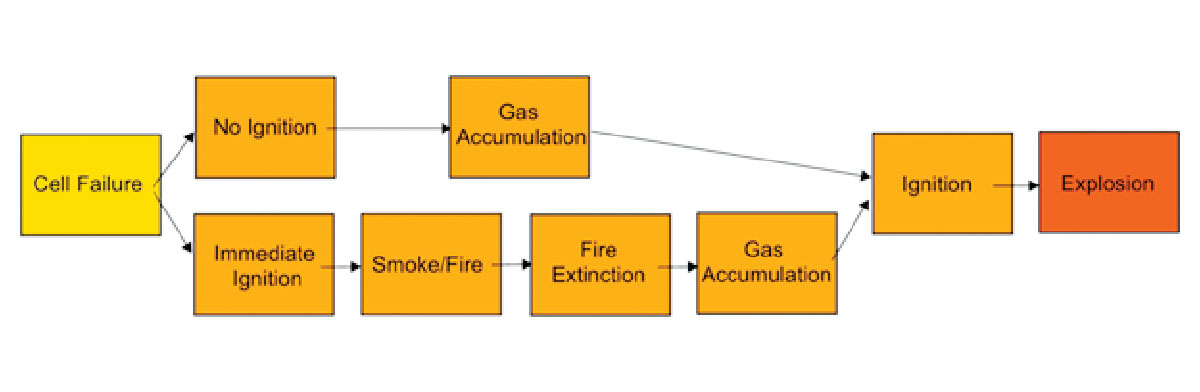

Extinguishment of lithium-ion battery cells when in the thermal runaway state has proven difficult, if not impossible. Instead, test programs of varying configurations have shown that mitigating the size of these fires by limiting fire propagation to additional cells and batteries is the most effective firefighting strategy. Fire tests have also shown that while the above stages are typical, they are not necessarily linear; sometimes fire is delayed, or even absent, as depicted in Figure 2 below.

* Picture of Lithium-ion Cell Failure Timeline (Graphic from Nexceris)

Multiple variables affect the sequence of events following cell failure, including the type and chemistry of cells, configuration of cells, capacity of cells and state of charge, ventilation, and types of safety systems. Test programs have shown that thermal runaway can occur without a flaming fire and that an uncontrolled release of flammable vent gases still occurs. This point was made especially clear in the analysis of the ESS explosion in Surprise, AZ. In this event, the Novec 1230 clean agent suppression system extinguished the fire even as the thermal runaway of cells continued and flammable vent gases continued to build up within the container. The Upper Explosive Limit was exceeded and so it was not until a door was opened and allowed air into the compartment that there was enough oxygen that allowed for the explosion to occur. A full, detailed account of this event and lessons learned is provided in the Underwriters Laboratories (UL) report from July 2020 titled “Four Firefighters Injured in Lithium-Ion Battery Energy Storage System Explosion – Arizona.”

Further documentation of the explosion risk is discussed in the UL technical report from April 2021 titled “UL 9540A Installation Level Tests with Outdoor Lithium-ion Energy Storage System Mockups.” In this UL report, deflagrations occurred in all three of the test scenarios [(1) no active fire suppression systems; (2) Novec 1230 clean agent system; and (3) dry pipe sprinkler system designed to provide 0.5 gpm/sqft.] because the gas concentrations inside the containers were not only above the lower flammability limit but “ultimately exceeded the upper flammability limit for the cell gas mixture.”

Vent Gas Production

The flammable gas that is expelled by lithium-ion batteries when in thermal runaway is a mixture of several flammable and toxic gases. The four gases that are produced in the largest quantities include Carbon Monoxide, Carbon Dioxide, Hydrogen, and Methane. The concentration and quantity of gases is highly dependent on the chemistry of the type of lithium-ion battery and the State of Charge (SOC) of the battery. Laboratory tests of different cell chemistries showed that the SOC strongly influences the volume production of vent gases and the rate at which the gases are released. In a 2021 report by EPRI, it was stated that the Mean volume of gas released per cell energy is estimated at 0.40 l/Wh and a Lower Flammability Limit of 10%. These results are based on tests of 21 varieties of lithium-ion chemistries at 100% SOC.

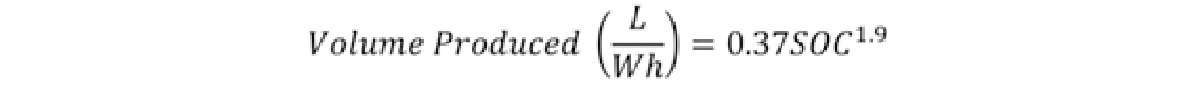

Another equation that is used to estimate the volume of vent gas produced, and that takes into account the state of charge, is:

At 100% SOC, this equation estimates the volume per cell energy to be 0.37 l/Wh which is similar to the EPRI report.

The variability of gas produced based on SOC is represented in the following chart that was presented in the SFPE webinar series “Lithium-Ion Batteries: What Fire Protection Engineers Should Know” (2020).

At higher SOC, the chance for thermal runaway increases as does the magnitude of energy released and vent gas produced. FM Global tests showed that the risk of thermal runaway is lower when the SOC is at 50-60% or less, and tests performed by the FAA, DOT, ICAO and others have shown the risk is minimal when cells are at an SOC of 30% or less. As discussed in the results of FM Global tests, commodity classification of lithium-ion cells at SOC of 50% or less is highly affected by the type of product packaging which is the “driving factor in the overall commodity.” This can also be understood as saying, low state of charge batteries present no greater fire risk than the packaging they are contained in. Further to this point, the Federal Aviation Administration (FAA) Technical Center found that the hazardous effects of thermal runaway were markedly less when the cells were at 30% SOC or less, and that the propagation of thermal runaway could be greatly reduced or eliminated at this SOC.

Deflagration Risk

At a typical solar installation and provider’s building, batteries will be received and stored in the warehouse at 30% SOC or less.

As described in section 2.2 above, based on the low SOC, vent gas production and thermal runway are greatly reduced. Upcoming changes to the 2022 CFC and 2024 IFC reflect this, in that at SOC of 30% pr less, storage of Li-Ion batteries does not require a technical report addressing deflagration hazard, does not require 2-hr fire barrier separation for battery storage and does not require explosion control.

Codes and Standards

The 2018 IFC and IBC do not contain specific requirements related to the storage of Li-Ion batteries.

The ICC code committee has provided guidance in the 2024 edition of the IFC for some scenarios involving the storage of lithium-ion batteries. Notably, Section 321.4.2.6 (in the proposed language for the 2024 IFC) allows for reduced requirements for “storage of partially charged batteries.” This section says that when batteries in indoor storage have an SOC that does not exceed 30%, that the deflagration analysis/technical report is not required, the 2-hour rated fire barrier separation from other occupancies is not required, and explosion control is not required. Regardless of these exceptions, the requirements for fire suppression and fire detection and alarm would still apply where Section 321 applies.

As of January 2023, the State of California Fire Code will include this same language as Section

322.4.2.6 of the State amendments to the fire code.

NFPA has issued the 2023 edition of NFPA 855 Standard for the Installation of Stationary Energy Storage Systems. Since the typical solar installation and provider company facility does not have ESS, NFPA 855 does not specifically apply. However, there is guidance for storage of batteries in Chapter 14 of the standard which, again, helps to inform the appropriate safety measures and design of this project. Similar to the 2024 IFC update, NFPA 855 Section 14.1.1 provides an exception for when lithium-ion batteries have a SOC of 30% or less. This further supports the opinion that a deflagration hazard is not probable for a typical solar provider company storage of low SOC batteries.

Also instructive to the proposed design are the test programs completed by UL, NFPA Research Foundation, FM Global, and the Technical Reference for Li-ion Battery Explosion Risk and Fire Suppression prepared by DNV-GL.

It is important for a solar provider company to note that these code requirements are likely to change over time as more testing is done and their results released to the code writing and engineering communities.

At this time, the protection strategies discussed and recommended below are based on the more current code language from the ICC in upcoming code publications and from the limited test data currently available.

Protection Strategy to Lithium-Ion Battery Storage in Warehouse

The following summarizes the various protection strategies used to address the hazards of lithium-ion batteries in storage within a solar provider’s current warehouse, whether stored on the floor or stored in the pallet racks, followed by recommendations for future storage sites and improved strategies for existing storage facilities.

Since current and previous codes did not specifically provide fire code or fire sprinkler design requirements, each facility required an alternative means of design to be approved by local building and fire department authorities on a case-by-case basis.

Current Solar Installation and Provider Company Sites

Current solar installation and provider company sites utilize 4 primary storage arrangements for Li-Ion batteries. All arrangements are for low SOC batteries (not exceeding 30%). Arrangements are: isolated on floor, bulk 1 high on floor to maximum 5ft tall storage height, bulk stacked on floor (over 5ft in height) and stored on racks to various heights. Some protection schemes seen in existing facilities include but are not limited to:

Isolated on floor

Sprinkler protection provided by overhead sprinkler system designed for the high- piled storage in the warehouse. This is based on the primary hazard being the fuel load of the packaging, low SOC and low storage height.

Bulk 1 high on floor to maximum 5ft tall storage height

Sprinkler protection provided by overhead sprinkler system designed for the high- piled storage in the warehouse. This is based on the primary hazard being the fuel load of the packaging, low SOC and low storage height.

Bulk stacked on floor (over 5ft in height) or for up to 15 foot high racks per FM 8-1 Section 2.4.2.

For storage up to 15ft in height with a maximum height to the underside of the roof deck/ceiling of 40ft, ESFR/storage sprinklers, K25.2 or K22.4 at 35psi minimum design pressure for 12 sprinklers. This is based on FM Global Research Report entitled “Development of Protection Recommendations for Li-Ion Battery Bulk Storage: Sprinklered Fire Test” and FM Global Data Sheet 8-1, interim revision dated April 2021.

Stored on pallet racks

For storage up to 15ft in height with a maximum height to the underside of the roof deck/ceiling of 40ft, ESFR/storage sprinklers, K25.2 or K22.4 at 35psi minimum design pressure for 12 sprinklers. This is based on FM Global Research Report entitled “Development of Protection Recommendations for Li-Ion Battery Bulk Storage: Sprinklered Fire Test” and FM Global Data Sheet 8-1, interim revision dated April 2021.

Stored on pallet racks

A combination of in-rack sprinklers and horizontal barriers. The in-rack sprinkler design with barriers is based upon recommendations in the same FM Global report which recommends a design for ignitable liquids in accordance with Scheme A from FM Data Sheet 7-29.

Future Solar Installation and Provider Company Sites/Upgrades to Existing Sites

Based on the new code guidance which will be formally adopted as statewide code in California as of January 1, 2023, a solar installation and provider company should consider, and will likely be required, for new sites and possibly for existing sites, to upgrade the protection schemes. Some possible criteria are noted below:

In all scenarios, installation of a fire alarm system in accordance with the 2023 CFC language should be considered.

322.4.2.4 Fire alarm systems

Indoor storage for lithium-ion and lithium metal batteries shall be provided with an approved automatic fire detection system complying with Section 907. The fire detection system shall use air-aspirating smoke detection, radiant energy-sensing fire detectors, or both.

Occupant notification provided throughout the solar provider company space in accordance with NFPA 72 should be considered.

Paragraph 322.4.2.1 item 2 states that “The basis of design for the automatic sprinkler system or other approved fire suppression system shall reference relevant full-scale testing or other approved method for demonstrating sufficiency of the recommended design.

Even with the newer code language from the 2023 CFC and 2024 IFC, sprinkler protection strategies will still require case-by-case approval from each local AHJ since there is still no prescriptive code language specifying the required fire sprinkler design criteria. This case- by-case approach is best handled by retaining the services of a fire protection engineering firm. In addition, it must be recognized that this report is current as of November 1, 2022. This field is changing so rapidly, that it will be necessary to research changes to the code at the time of any project.

Construction Documents for High Piled Storage

From IFC Chapter 32, Section 3201.3 a site-by-site analysis is still required for all of the typical high piled storage issues required for high piled storage permit application. This would include at a minimum; storage arrangements, sprinkler and fire alarm requirements, smoke vents, fire apparatus access, fire fighter access doors, fire extinguishers, exit travel distance, etc. Within the documentation for each site, the specific arrangement and protection strategy for the Li-Ion batteries will need to be addressed. Even as the newer fire code requirements are adopted, the fire sprinkler protection scheme will still need to be approved locally for each case as an alternative means of design.

Conclusions

Lithium-ion cells present unique fire and explosion hazards when charged at high SOCs and during charging operations. At low SOCs, and especially below 30% charge, the risk of thermal runaway, cell to cell propagation, and explosion hazards are reduced. This is supported by the research discussed above and by the new IFC code language exempting low SOC (30% or less) from explosion control and 2-hr fire barrier separation.

However, the unique fire challenge of lithium-ion batteries must be addressed.

The fire protection design strategy of the solar installation and provider company warehouse should recognize these challenges and provide for proper fire sprinkler and fire alarm system installation.

One recommended protection strategy may include automatic sprinkler systems at the ceiling level and in-rack storage per FM Global research when the ceiling level system alone does not mesh with the available relevant fire testing; early warning fire detection by air sampling smoke detection and occupant notification throughout the solar provider warehouse space. Again, any protection strategy should be addressed on a case-by-case basis with your fire protection engineer due to the many variables involved with this rapidly evolving technology.

If more information or an in-depth evaluation of your storage requirements is needed, please contact your professional material handling company and/or experienced fire protection engineer.

Carl Anderson, PE

Registered in CA, WA, OR, UT, ID, AZ, NV, OK and FL

The Fire Protection International Consortium, Inc.

360-878-9267

www.the-fpi.com